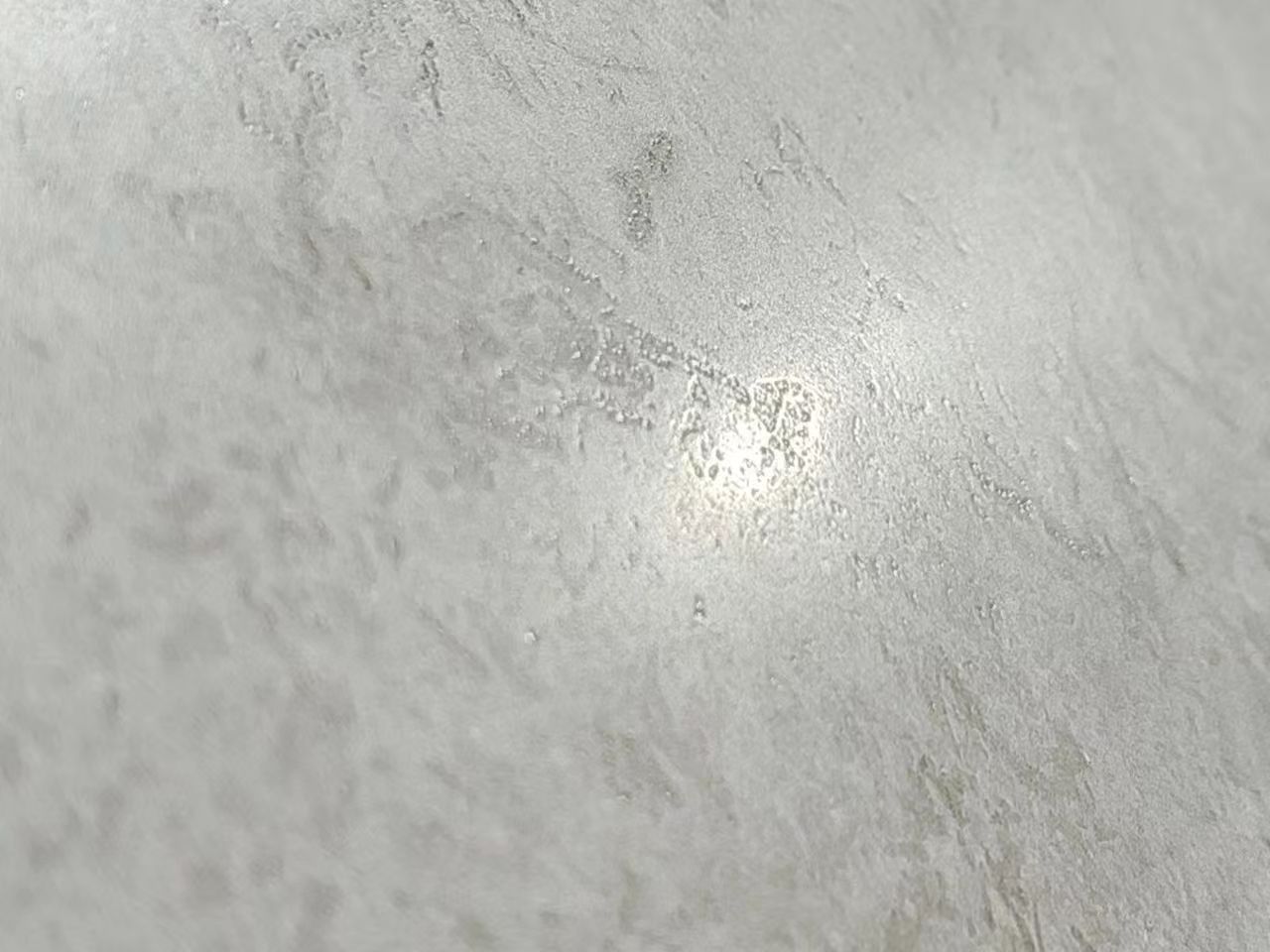

Mmodzi wapadera pamwamba wakhala wotchukazaka ziwiri izi, makamaka mu makampani ceramic matailosi.Imaphatikiza zomaliza zakale ndi za satin, zomwe zimapereka luso loletsa kuyipitsa komanso kuyeretsa kosavuta.

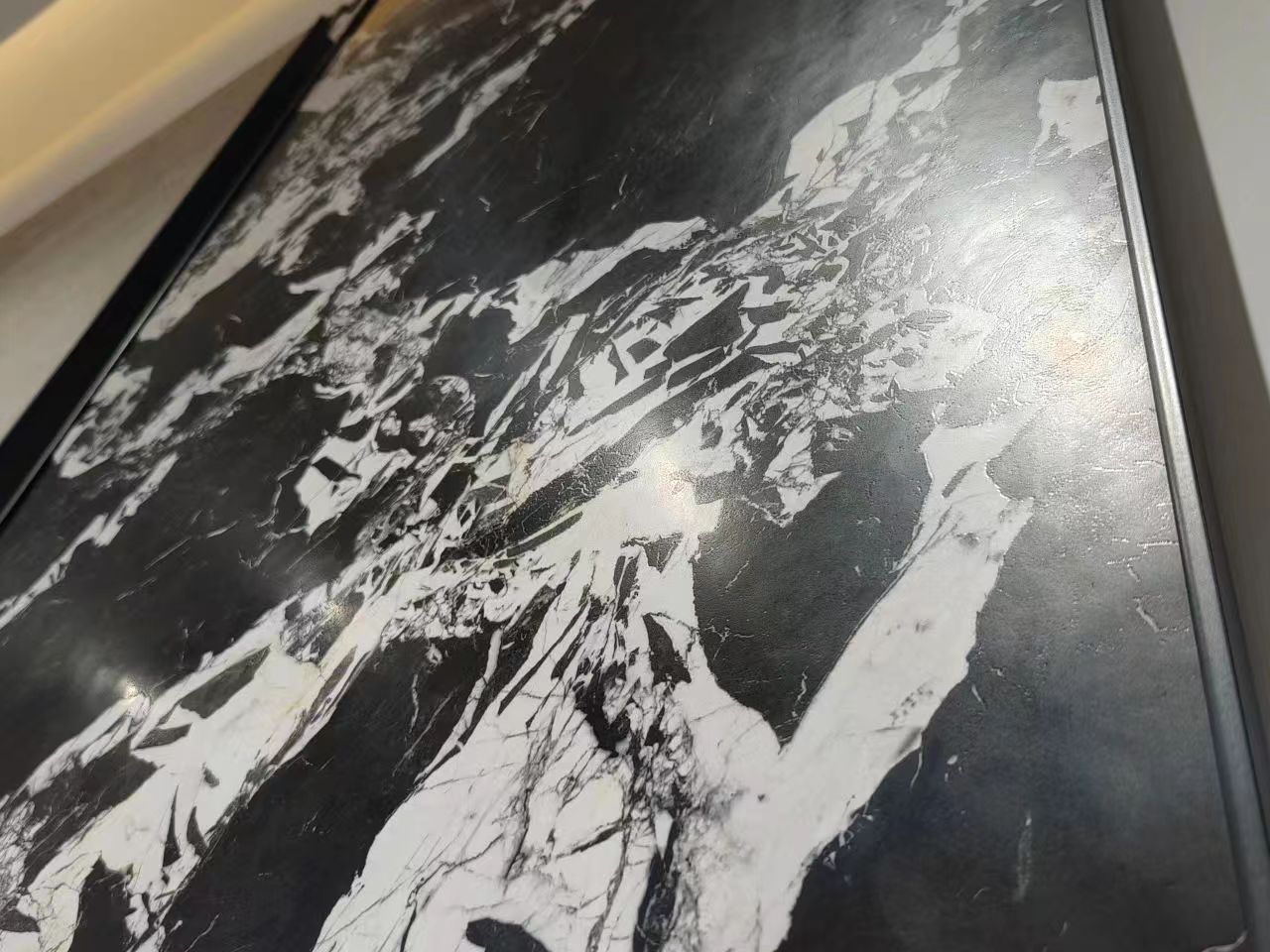

Malo apaderawa amafanana ndi mwala womwe unayikidwa m'matchalitchi a ku Ulaya ndi mipingo, kupereka maonekedwe okalamba omwe amachititsa chidwi cha mbiri yakale.Imajambula bwino kwambiri mwala wachilengedwe, kubwezeretsa mawonekedwe ndi kuwala kwa marble.Kumwamba kumakhala ndi mawonekedwe akale, onse osalala ngati satin komanso owoneka ngati mawonekedwe atatu.Kuphatikiza apo, imapereka kuwala kofewa komanso kumva kwakale, kuwunikira mbiri yakale ndi nkhani.

Anzanu ena atha kukhala ndi chidwi chofuna kudziwa momwe angakwaniritsire izi komanso zida zomwe zimagwiritsidwa ntchito.

Mwachitsanzo, mu ceramic indutry, ndondomekoyi imagawidwa m'masitepe atatu: kupanga malo akale, kusalaza pamwamba, ndi kugwiritsa ntchito mankhwala oletsa kuipitsa.Zida zonyezimira zogwirizana ndi maburashi onyezimira, zopukutira za diamondi za siponji, ndi zakumwa za nano.

1. Burashi yakale ya diamondi kapena burashi yakale ya silicon: Kugwiritsa ntchitoburashi yakalePogaya matailosi a ceramic (mwala) pamwamba pake, ndikumakokoloka ndi mawaya owopsa, kuchotsa njere zofewa kuti apange malo opindika ndikusiya zolimba zosalala pambuyo popukuta.

2. Kufewetsa ndi kukulitsa gloss: Kuti mukwaniritse malo a satin, gwiritsani ntchitosiponji diamondi kupukuta ziyangoyangondi grits 120 #, 180 #, 240 #, 320 #, ndi 400 #.Mapadi awa amatha kukulitsa kuwala mpaka madigiri 15-35.

3. Kugwiritsa ntchito mankhwala amadzimadzi: Gawo lomaliza limaphatikizapo kuphimba pamwamba ndi mankhwala amadzimadzi kuti ateteze kuipitsidwa ndi madontho a tiyi, khofi, mafuta, ndi zina zotero. Sitepe iyi imawonjezeranso pang'ono glosness ndikuphimba ting'onoting'ono tating'ono zomwe sizikuwoneka ndi maso.

Ngati mukufuna kudziwa zambiri, chonde omasuka kulankhula nafe nthawi iliyonse.

Nthawi yotumiza: Jul-16-2024