1.Kodi mwala wakale ndi chiyani?

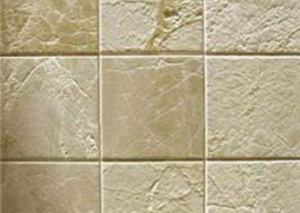

"Mwala wakale" umatanthawuza chithandizo chapadera cha granite yachilengedwe kapena marble, kotero kuti pamwamba pa mwala pali mafunde achilengedwe kapena ming'alu yofanana ndi nyengo, ndipo panthawi imodzimodziyo, kuvala kwachilengedwe kwa mwala pambuyo pogwiritsira ntchito nthawi yaitali ( pafupifupi matte kapena mercerized effect)).Kawirikawiri, ndiko kukonza mwala wachilengedwe kuti ukhale ndi zotsatira zachikale zomwe zimawoneka ngati zakhala zikugwiritsidwa ntchito kwa zaka mazana ambiri.

2. Ubwino wa miyala yakale processing.

Kukonzekera kwamwala wakale kumatha kukhala ndi zotsatira zofananira za satin mercerizing, kuwonetsa kuwala kwamwala wachilengedwe, ndikusewera mawonekedwe apadera okongoletsa;nthawi yomweyo, imathanso kupititsa patsogolo ntchito yoletsa kuwononga komanso yopanda madzi yamwala, ndipo imatha kusewera ndi anti-slip effect.Kapangidwe kakale ka miyala kamathanso kupewa kuipitsidwa ndi kuwala m'nyumba chifukwa cha mawonekedwe apadera a kuwala.Panthawi imodzimodziyo, mwala wakale ndi wosavuta kukonzanso pambuyo pa kuvala.Panthawi imodzimodziyo, chromatic aberration ya mtundu ndi yaying'ono kusiyana ndi njira yopukutira, ndipo imatha kuwonetsa bwino lingaliro lamtengo wapatali la chitetezo cha chilengedwe.

3.Zida zazikulu za abrasive zopangira zakale zamwala wachilengedwe.

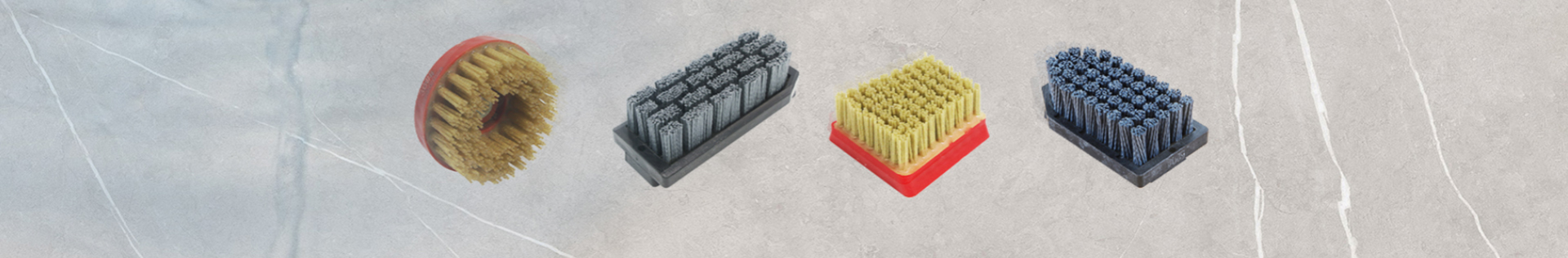

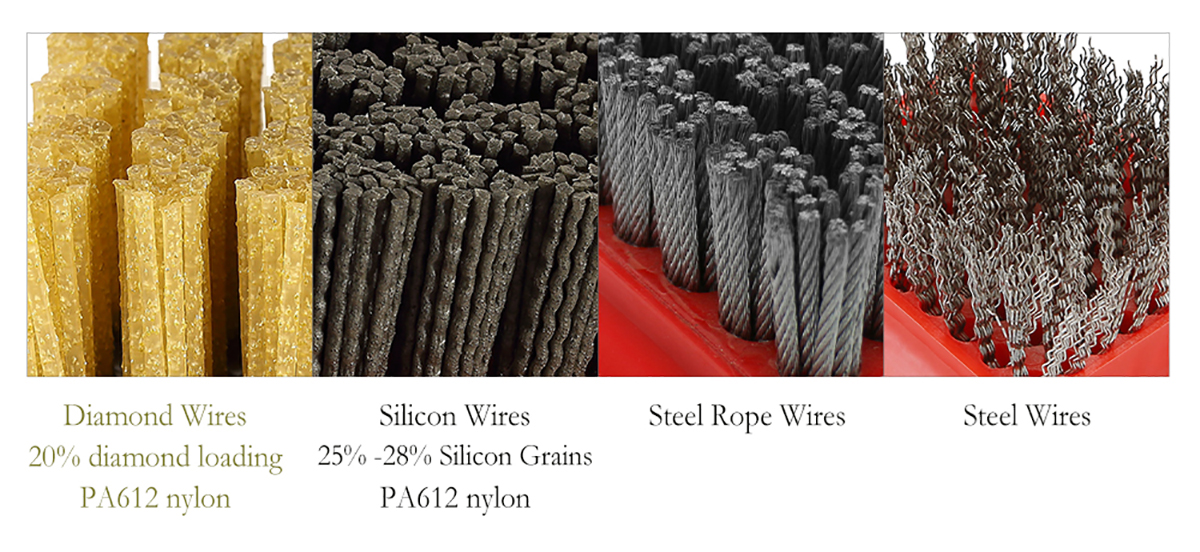

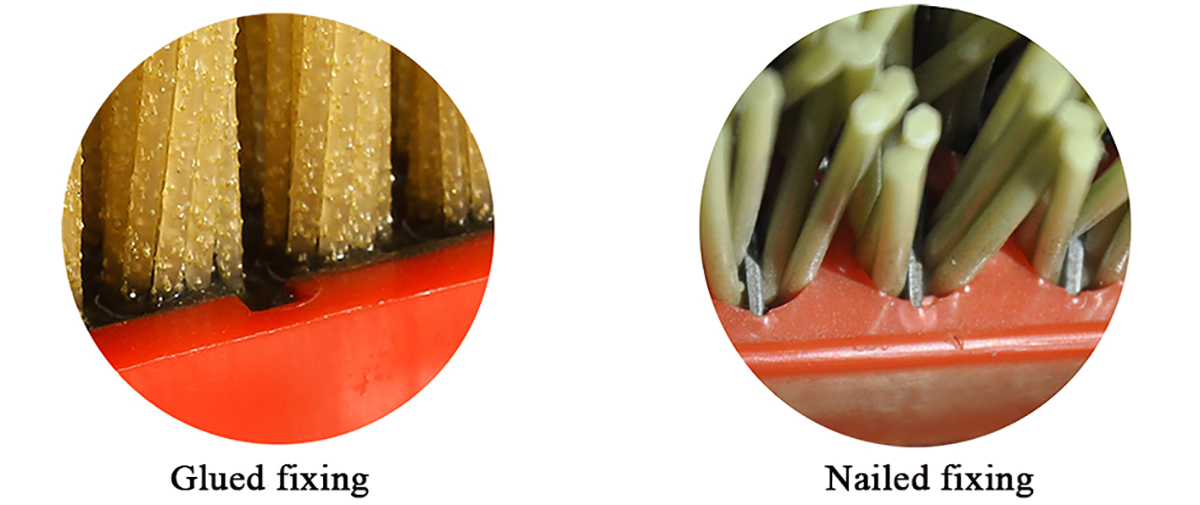

Maburashi abrasive ndi zida zazikulu zopangira zinthu zakale, nthawi zambiri zidapangidwa ndi mawaya 4: diamondi, silicon carbide, chitsulo, chingwe chachitsulo. Kenako kuyika mawayawa mupulasitiki kapena plinth yamatabwa, kukonza mawaya ndi guluu kapena zitsulo zomangira (zokhomerera misomali) .

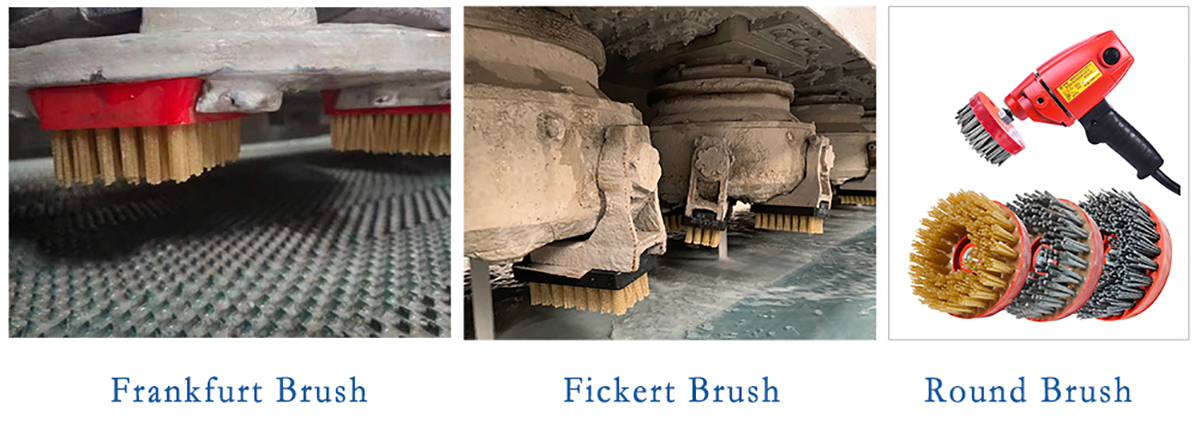

Tidasanja abrasive m'mitundu itatu molingana ndi mawonekedwe osiyanasiyana ndi makina ogwiritsira ntchito:frankfurt brush, burashi ya fickertndi burashi yozungulira.

Nthawi zambiri, burashi ya frankfurt imagwiritsidwa ntchito pamakina opera pamanja, mzere wokhazikika wokhazikika (wopukutira nsangalabwi, terrazzo), makina okonzanso pansi, etc.

Burashi yozungulira imagwiritsidwa ntchito pamakina ang'onoang'ono opukuta pamanja, makina okonzanso pansi;

Burashi ya Fickert imagwiritsidwa ntchito pamakina ongopeka mosalekeza popukuta granite kapena matailosi a ceramic kapena quartz yokumba.

4. Mayendedwe opangira zinthu zakale za miyala yachilengedwe (mwachitsanzo granite).

Chifukwa cha kulimba kwa granite, choyamba gwiritsani ntchito moto kapena madzi oponderezedwa kwambiri pokonza mbale ya granite kukhala mbale yoyaka moto kapena mbale yoyipa (ingathenso kusinthidwa kukhala mchenga wa lychee sandblasting, ndi zina zotero, koma zotsatira zake sizowona. chabwino), pamwamba pake payenera kukhala movutikira kuposa bolodi loyimbira wamba, kuti matabwa amiyala asakhale osalala kwambiri mukamagwiritsa ntchito burashi yopera mwala mu sitepe yotsatira, zomwe zingapangitse kuti masanjidwewo atayike mawonekedwe ake amitundu itatu.

Pambuyo pake, molingana ndi zofunikira za kasitomala, gwiritsani ntchito maburashi abrasive kuchokera ku mesh coarse mpaka ma mesh abwino kuti akupera ndi kupukuta motsatizana mpaka bolodilo lifika pazomwe zimafunikira ndi gloss.Ngati kasitomala amafuna kukwaniritsa yosalala ndi matte zotsatira, ayenera kugwiritsa ntchito diamondi burashi 36 # (kapena 46 #), 60 # (kapena 80 #), 120 # (kapena 180 #) njira zinayi;kuti mukwaniritse zotsatira za mercerized, muyeneranso kuwonjezeraburashi ya silicon carbide240 #, 320 #, 400 # njira zitatu, ndithudi, ngati njira zonse zichitidwa, zotsatira zake zidzakhala bwino.

5.Kuthamanga kwa kayendedwe ka malo akale a marble achilengedwe

Chifukwa cha mitundu yosiyanasiyana ya miyala ya miyala ya miyala ya miyala ya marble, njira yopangira ma marble iyenera kusankhidwa malinga ndi kusiyana kwa maonekedwe a mabulosi osiyanasiyana.

Marble yokhala ndi calcium yambiri ndi magnesium carbonate kapena ming'alu ndi mabowo amatha kunyowa pomira mu hydrochloric acid kwa mphindi 10-20 (malingana ndi mwala wamtundu wanji);pambuyo pake, gwiritsani ntchito burashi yachitsulo kuchotsa zotsalira za ming'alu ndi mabowo kuti muwonjezere pamwamba pa mwala.Pomaliza, gwiritsani ntchito maburashi onyezimira kuchokera ku mesh ya coarse kupita ku mesh yabwino kuti mupere ndi kupukuta motsatizana mpaka pamwamba pa bolodi ifika pa gloss yomwe kasitomala amafunikira.

Ngati ndi nsangalabwi yokhala ndi calcite yambiri, imatha kukonzedwa mwachindunji ndi burashi yachitsulo.N'zothekanso kutsuka m'mbali atatu azithunzithunzi pamwamba zotsatira ndi zitsulo waya burashi choyamba, ndiyeno pogaya ndi kupukuta sequentially ndi akupera burashi kuchokera coarse mauna kuti mauna abwino, kawirikawiri ntchito 36 # 60 # 80 # diamondi burashi ndi 180 # , 240 #, 320 #, 400 # silicon burashi kuti processing.Ngati ndi nsangalabwi yolimba, masitepe am'mbuyomu akhoza kuonjezedwa moyenera.

Chonde khalani omasuka kulumikizana nafe ngati muli ndi chidwi, ndife okondwa kukuthandizani.

Elain: +86-13336414847(Whatsapp / Wechat),email:expert01@huirui-c.com

Alice: +86-13336448141(Whatsapp / Wechat),email:expert02@huirui-c.com

Nthawi yotumiza: Apr-24-2023